The use of automated machinery such as computer numerically controlled (CNC) technology in steel fabrication creates several advantages in wire forming. These same advantages can also be seen in the manufacture of straight and cut wire.

Wire is used in many industries today, from automotive and agricultural to household appliances and many more. These wires can be small, intricate pieces designed to carefully carry out delicate functions or large pieces used for support and framing. Whatever the application, you’ll want to ensure that you have a consistent and reliable product at the end of the line.

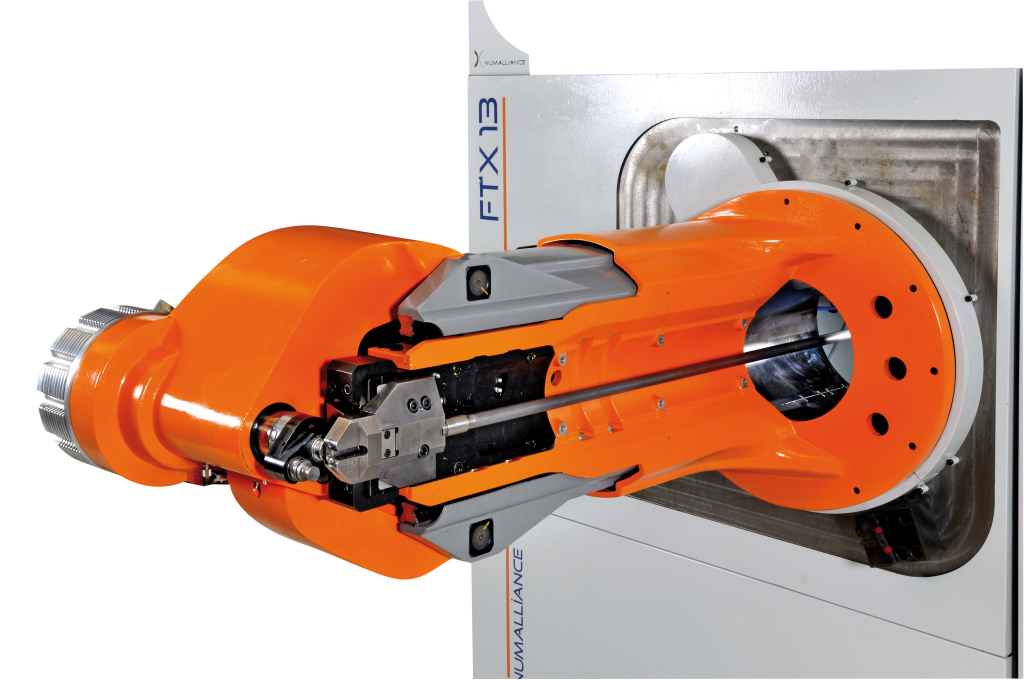

That’s where CNC technology can be beneficial. However, before we get into the benefits, it’s helpful to have a solid understanding of how the technology functions. CNC technology works through pre-programming a computer to create custom designs and shapes out of wires from different materials for specific qualities.

This pre-programming creates a specific pattern of physical manipulation that the wire will undergo in the machine in order to create the desired shape. The wire is first rolled through wheels, which straighten the wire. The wire is then passed through die and pins until the shape is achieved, when the wire will be cut off.

The benefits of CNC technology have revolutionised the way that wire forming and steel fabrication works today. The use of the computer to pre-program the design means that each individual piece can be created much faster, as human hands don’t have to shape and check each unit. The machine can simply be programmed, and then each unit will be made as identical standard pieces.

Due to the computer technology involved, the process also allows for more complex shapes to be made, with multiple identical copies being created very quickly, with less waste and less time consumed. It also costs less per unit created, even for shorter runs.

This technology is also able to work with both 2D and 3D structures, so it is able to create a wide range of products for almost any application. Additionally, the technology allows the changeover between runs of 2D and 3D structures to occur in less than one hour, which cuts down on manufacturing time and costs and results in less time taken in getting the product to you.

Different materials can be used to give the end product different qualities. For instance, a coating of chrome can help to give the end product resistance to rusting, which is important if the product is likely to be exposed to the outside elements or often in contact with water or oxidising elements.

Zinc is also an excellent choice as a coating material, as it is protective against corrosion. Corrosion can be a significant problem in certain wire product applications, so if you have experienced that problem before, try a zinc coating to alleviate the issue. This can help to reduce the frequency of replacement parts, and to extend the life of your products.

Alternatively, wire can also be covered with nylon, which offers a unique resilience to abrasion and is a great choice for wires that are in environments that have a lot of movement. Nylon is also very resistant to acidic environments and can hold up well in environments such as sewers. All of these materials can be used with CNC technology to create unique wire products for your projects.

The benefits of CNC technology show how useful this technology can be, and this is emphasised by the adoption of the technology by the industry. Nowadays, the issue is finding the right team to work with to create the perfect solution for your project.

Ace Wire Works

Ace Wire Works is a local Australian wire and metal fabrication company that wants to work with you to create the highest quality wire products necessary for almost any application.

They can leverage their CNC technology with your imagination to create unique 2D and 3D structures suitable for almost any task, as well as provide a bevy of pre-fabricated designs and structures.

Using the CNC machines they have on site will be a breeze, with technicians able to develop any of your ideas from initial plans through to a fully realised product right here in Australia. Each member of the team has a great depth of product and industry knowledge to support their ability to use the state-of-the-art machinery held within this top notch facility.

Ace Wire Works has a range of wire options available, including both wire forming for 2D and 3D structures, and straight or cut wire that can be trimmed to length for projects as necessary.

They also have a variety of materials available, including mild spring, spring steel, stainless steel, galvanised steel, with finishes of chrome, zinc, nylon, or powder coating. With such a range of options, it’s no wonder the technicians have such broad expertise in all things wire!

To get your project started off on the right track, contact the friendly team at Ace Wire Works today.